-

Epoxy Resin Insulator

-

Medium Voltage Insulators

-

High Voltage Epoxy Resin Insulator

-

Vacuum Circuit Breaker

-

Epoxy Resin Bushing

-

Electrical Switchgear Components

-

Cast Resin Transformer

-

Earthing Switch

-

Copper Electrical Contacts

-

High Voltage Disconnect Switch

-

Zinc Oxide Lightning Arrester

-

Industrial Cable Ties

-

Electrical Conduit Plastic Pipe

-

High Voltage Indicators

-

Moulded Case Circuit Breaker

-

Load Breaker Switch

-

Power Distribution Transformer

-

StephanQiuPu is a great electric power factory. we satisfy you very much . will cooperate with you again!

StephanQiuPu is a great electric power factory. we satisfy you very much . will cooperate with you again!

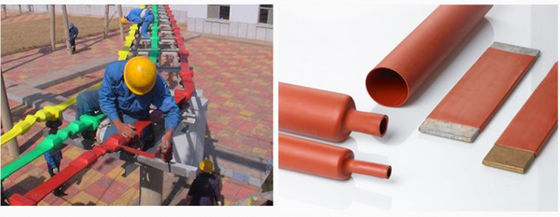

Colored Heat Shrink Busbar Electric Junction Box Insulated Protection Cover

| Color | Red/Yellow/Blue | Type | 100X10/50X10/80X10/120X10 |

|---|---|---|---|

| Voltage | 1kV-35kV | Shape | I/X/T |

| Highlight | underground electrical conduit pipe,heat shrink wrap tubing |

||

MPH10 Bus-bar Conjunction Box With High Voltage Switchgear Copper Row

1. The silicone tube and the silicone rubber tube are the same thing, just called different. The utility model relates to a general-purpose heat-shrinkage sleeve made by using two-component high temperature silica gel as the base material, adding a fixed ratio additive, and forming material by several vulcanization.

It has the functions of high temperature shrinkage, soft flame retardant, insulation and corrosion prevention. When heated, the inner diameter of the casing quickly shrinks to half, and the protected electronic parts are tightly encased in the casing to protect the electronic original, acting as insulation and temperature resistance. It is widely used in various wire harness, welding spot, inductance insulation protection, metal pipe, rod Rust, corrosion, etc. Voltage class 600V.

Material can be divided into PE heat shrink sleeve, PTFE heat shrink sleeve, silicone heat shrink sleeve, PVC heat shrink sleeve, pet heat shrink sleeve, irradiated cross link PE heat shrink sleeve, 10KV high pressure master protection heat shrink sleeve, 35KV high pressure master protection heat shrink sleeve, double wall heat shrink sleeve, heat shrink sleeve .

Different types of thermal shrinkage time and temperature are different.

PVC and PET type, minimum contraction temperature 35 ℃, but at this temperature is very weak contraction, so this type of products should be stored below 30 ℃. The minimum temperature of rapid contraction is above 90 ℃.

2. The shrinkage temperature of the PO thermotube is 90 ℃ and 110 ℃, respectively.

For PE and PVDF, the shrinkage temperatures reached 125 ℃ and 150 ℃ or 175 ℃ respectively. The contraction temperature of PTFE material is over 200 ℃.

PVC thermal tube

PVC heat shrink sleeve has the special function of heating contraction, heating over 98 ℃ can contract, easy to use. The products are divided into 85 ℃ and 105 ℃ according to the temperature tolerance two series, the specification is 2-can 200, the product conforms to the European Union RoHS environmental directive. Used for electrolytic capacitor, inductor, good high temperature resistance, no quadratic shrinkage, can be printed. Used for various rechargeable battery monomer, combination packaging, and for design, printing patterns, and can be cut for customers. Used for covering all kinds of curtain rod, bath rod, hanging rod, mop rod, broom handle, tool rod, telescopic rod, garden tool, pole and so on. It can be used for the identification and insulation outer coating of low pressure indoor busbar, joint and wire bundle. High efficiency, low investment in equipment and low overall cost. The package used for lighting, LED pins, as well as the guitar, packaging bottle, is the new packaging material. Whether it's civilian, vehicle or military, it's the first choice.

PET thermo tube

PET thermo-shrink tube(polyester thermo-shrink tube) from the thermal resistance, electrical insulation, mechanical properties are greatly exceeded by the PVC thermo-shrink casing, more importantly, PET thermo-shrink tube is non-toxic, easy to recover, will not toxic effects on the human body and the environment, more environmental requirements.

The environmental performance of PET thermotubes is higher than that of the European Union RoHS Directive, which can meet the Sony SS-00259 environmental standards. The environmental performance of PET thermotubes is higher than that of the European Union RoHS Directive, which can meet the Sony SS-00259 environmental standards. Cadmium(Cd), lead(Pb), Mercury(Hg), hexavalent Chromium(CrVI), PBBs, PBDEs and PCBs, PCB(PCB), PCB(PCT), PCN(PCN), PCN(PCN), etc.. Fully meets export requirements.

3. The thermoplastic tube is a thermoplastic tubular material, also called the thermoplastic tube, some people also called thermoplastic tube. It is widely used in electronic, electric, electrical, mechanical and other industries. It is mainly used for insulation and protection, but also for various other uses, such as decoration. So for different applications, there are different materials of the thermal shrink casing. The so-called material is actually a comprehensive material formula, including a variety of materials, mainly the main materials, flame retardants, plasticizers, antioxidants and so on. The main material, of course, is the material that determines the main properties of the tube, and the auxiliary material can increase or increase some properties, so when we talk about the material of the heat casing, it actually means the main material. According to the current product series, the main materials can be divided into PE polyethylene heat shrink casing, PVC heat shrink casing, PET heat shrink casing, Tieflon heat shrink casing, EVA heat shrink casing, rubber heat shrink casing and other new materials heat shrink casing and so on.Some people also say that polyolefin thermal condensation casing, polyester thermal condensation casing, in fact, these two are a general term, olefins and esters are a large category of chemicals, such as our polyethene, polyvinyl chloride is a polyalkene, PET is a polyester. There are, of course, differences, even if they are also polythene thermosetting, because polyethylene is divided into many categories, such as HDPE, which has only a small number of short chains. Low density polyethylene(LDPE) molecular chain is a large number of long chain branched; Linear low density polyethylene(LLDPE), not containing long chain branched, but containing short side branched, "linear" means no long chain branched .

| Mode | Specification | |

| L , T , I , X | 80*10 , 100*10 | |