-

Epoxy Resin Insulator

-

Medium Voltage Insulators

-

High Voltage Epoxy Resin Insulator

-

Vacuum Circuit Breaker

-

Epoxy Resin Bushing

-

Electrical Switchgear Components

-

Cast Resin Transformer

-

Earthing Switch

-

Copper Electrical Contacts

-

High Voltage Disconnect Switch

-

Zinc Oxide Lightning Arrester

-

Industrial Cable Ties

-

Electrical Conduit Plastic Pipe

-

High Voltage Indicators

-

Moulded Case Circuit Breaker

-

Load Breaker Switch

-

Power Distribution Transformer

-

StephanQiuPu is a great electric power factory. we satisfy you very much . will cooperate with you again!

StephanQiuPu is a great electric power factory. we satisfy you very much . will cooperate with you again!

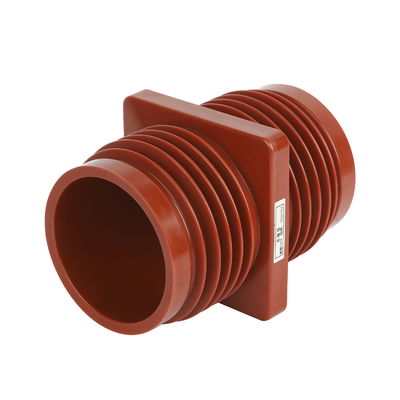

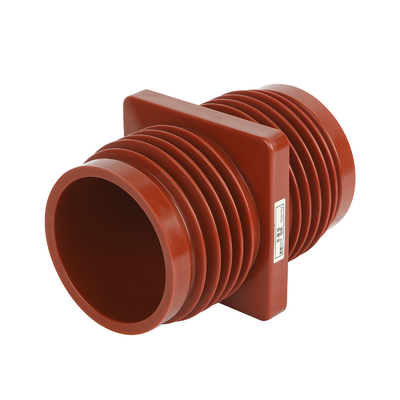

Wall Feed Through Epoxy Resin Cast Bushing Insulating Cylinder TG1-12Q/152X152

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Epoxy Resin/Casting | Color | Red/Brown |

|---|---|---|---|

| Rated Voltage | 12kV | Creepage Distance | 240mm |

| Length | 246mm | Strength | 8 KN |

| Frequency Coltage | 42kV | Craftwork | APG |

| Highlight | epoxy resin cast bushing,wall through bushing |

||

TG1-12Q/152X152 Casting Resin Insulator Swicthgear Wall Spout Bushing with Ring Net Cabinet Switchgear

1. Basic characteristics of liquid ring-to-fat automatic pressure gel(APG) process:(1) epoxy resin mixture at room temperature(25 ℃), the system suitable for 1-2 days; At 40 ℃ to 45 ℃, the applicable period is 6 to 8 hours. At high temperature(140 ~ 160 ℃), the formulation system is highly reactive, which can be controlled and guaranteed by reliable equipment and process parameters.

2.The mold temperature of the product is about 80 ~ 100 ℃ higher than that of the epoxy mixture system, so that the gelation process of the solidification reaction spreads from the mold wall to the intermediate epoxy mixture.

3. During the process of solidification reaction of the whole epoxy resin system, the pressure of the mixture is maintained, and the mixture system is squeezed into the mould chamber at constant pressure.

| Busbar | 100*10 |

| Busbar | 90*18 |

![]()

![]()